Driving Energy Efficiency and Operational Excellence in Cold Warehouses Through Smart IoT-Based Monitoring

Cold Chain Infrastructure

UN SDG 07 -Affordable and Clean Energy

Bangalore

Pain Points

Cold room managers struggle with high energy costs, lack of visibility, and unexpected equipment failures.

Rising Energy Bills

Uncontrolled cooling loads and poor visibility into energy usage lead to high and unpredictable monthly costs.

Lack of Real-Time Monitoring

Without live energy tracking, inefficiencies and anomalies go unnoticed until bills or equipment failures appear

Unplanned Equipment Downtime

Sudden compressor or chiller failures disrupt storage conditions, risking spoilage and operational losses.

Our Offerings

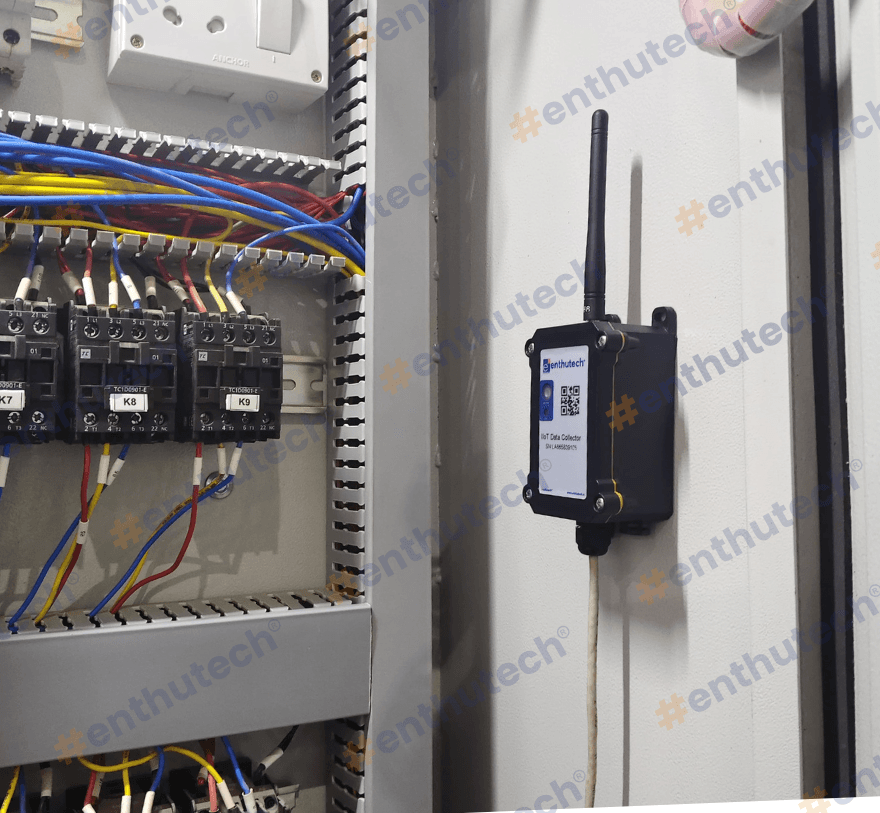

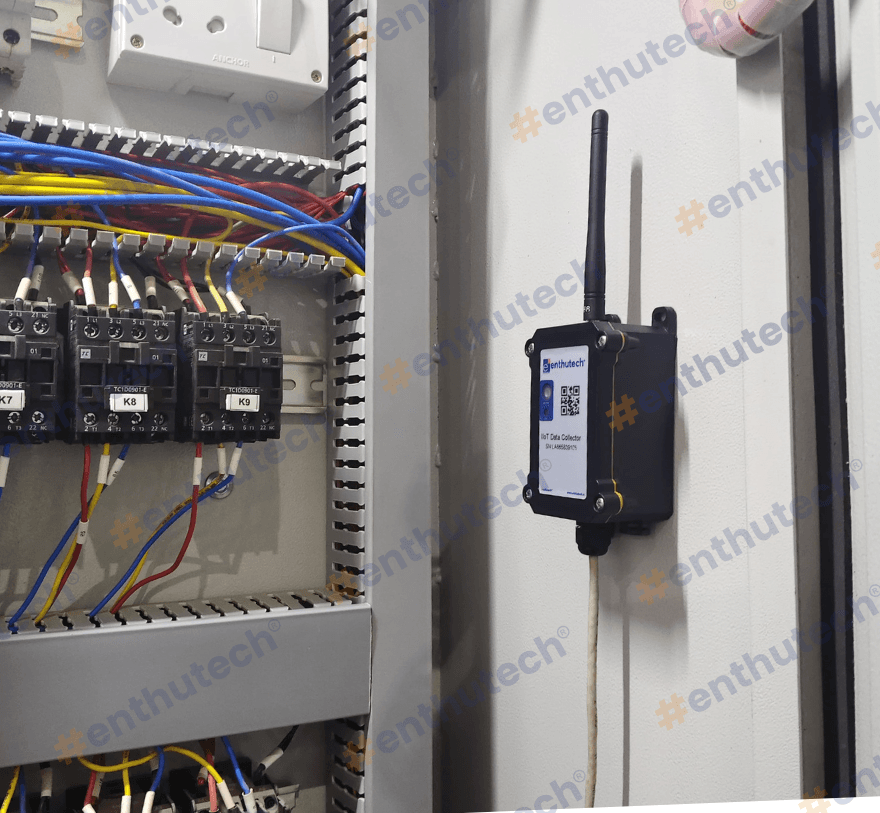

We delivers IoT-powered cold room energy monitoring for efficiency, savings, and reliability.

Real-Time Energy Monitoring

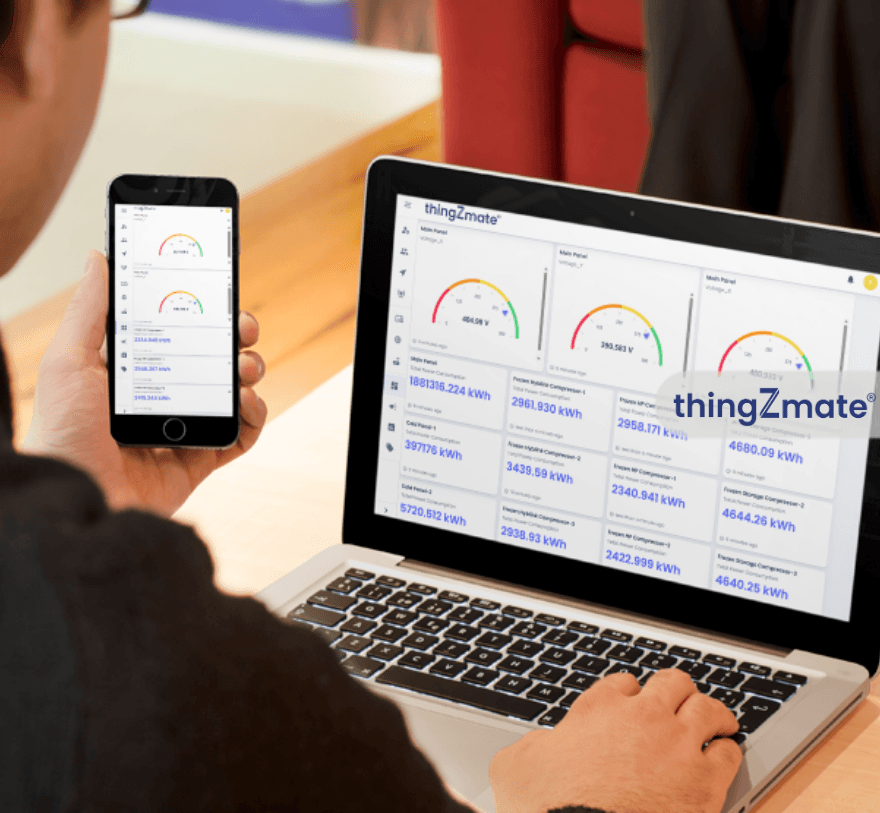

Track energy usage across compressors and chambers with live dashboards for instant visibility.

Smart Alerts & Notifications

Get instant alerts on abnormal consumption or failures to prevent losses and reduce downtime.

Predictive Maintenance Support

Data-driven insights detect equipment anomalies early, ensuring smooth, reliable cold room operations.

Cost & Efficiency Optimization

Optimize load distribution and reduce peak demand to lower bills and maximize energy efficiency.

Outcomes

Reduced Energy Costs

Smart monitoring and control lower electricity bills by 20–25%, improving profitability.

Improved Equipment Uptime

Early anomaly alerts cut downtime, ensuring cold rooms run reliably without disruptions.

Enhanced Product Safety

Stable temperature and humidity conditions protect goods, reducing spoilage and losses.

Data-Driven Decisions

Real-time dashboards and reports enable managers to optimize operations with actionable insights.

Smart energy insights turned challenges into savings, reliability, and better cold room performance.

Smart energy insights turned challenges into savings, reliability, and better cold room performance.

Get in Touch

© 2025, Enthu Technology Solutions India Pvt. Ltd. All Rights Reserved.