Energy Control and Monitoring for Cold Room Management: Enhancing Efficiency and Reducing Costs with IoT

Warehouse

UN SDG 9 - Industry, Innovation and Infrastructure

Bangalore

Pain Points

The customer faced high energy consumption in cold rooms, leading to excessive costs and inefficiency.

High Energy Bills

Cold rooms were consuming more energy than necessary due to lack of monitoring and control.

Inefficient Temperature Regulation

Fluctuations in temperature caused operational inefficiencies, affecting product quality.

Lack of Real-Time Data

Managers lacked real-time visibility into energy usage and operational performance.

Our Offerings

We delivered a solution integrating energy control and monitoring with real-time data analytics.

IoT-Enabled Energy Meters

We installed energy meters to track real-time energy consumption in the cold rooms.

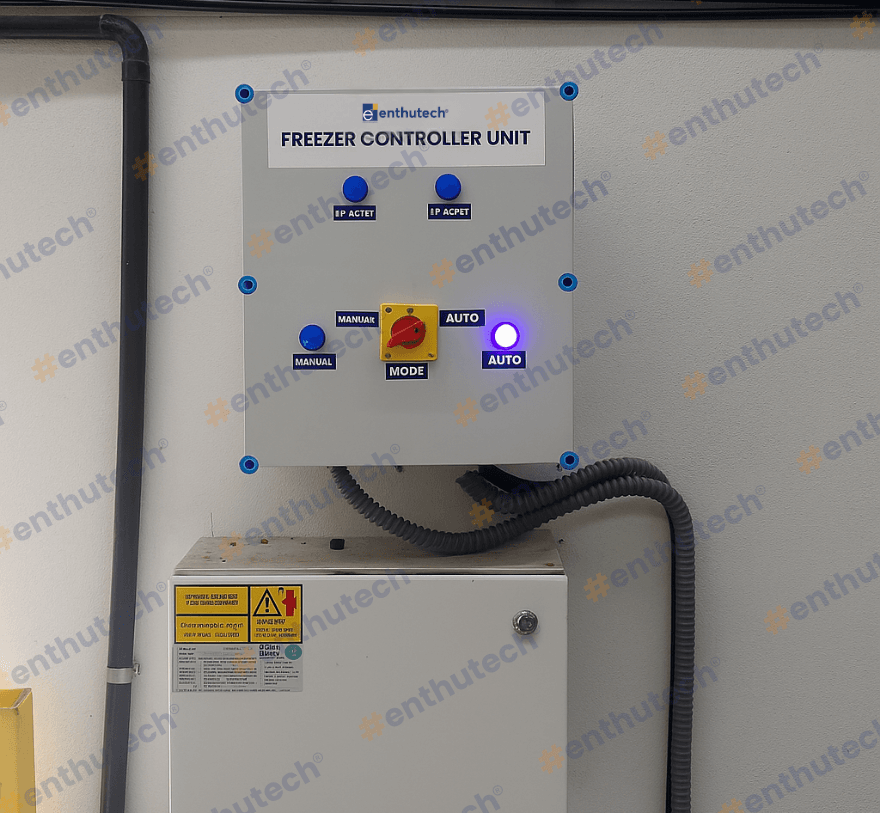

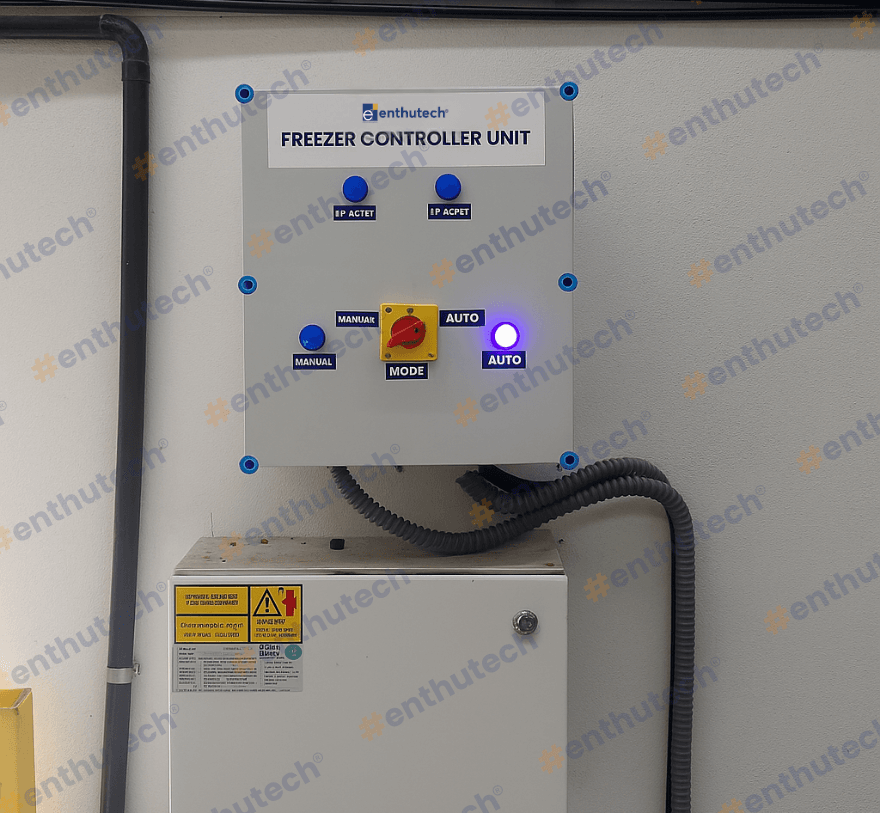

Smart Controllers for Temperature

Our smart controllers automated temperature regulation, ensuring energy efficiency.

Cloud-Based Dashboard

A centralized dashboard displayed real-time data on energy use, temperature levels, and alerts.

Predictive Maintenance Alerts

Alerts for potential energy inefficiencies and maintenance requirements were generated proactively.

Outcomes

Reduced Energy Costs

Energy consumption dropped by 25% due to optimized usage and automated regulation.

Improved Temperature Stability

Temperature fluctuations were minimized, ensuring better product preservation.

Increased Operational Efficiency

Real-time monitoring helped identify and fix inefficiencies quickly, improving overall operations.

Scalable Solution

The system is now scalable, allowing for future expansion to other facilities.

“Our energy costs have reduced significantly, and the cold rooms now operate with optimized efficiency.”

“Our energy costs have reduced significantly, and the cold rooms now operate with optimized efficiency.”

Get in Touch

© 2025, Enthu Technology Solutions India Pvt. Ltd. All Rights Reserved.